Corrugated Printing Methods for Commercial Carton Production ij

Corrugated paper—better known as cardboard—is one of the most useful materials ever created. Nearly every corrugated box has something printed on it to convey various types of information. Depending on your industry, type of products, and other factors, you may need to outfit your corrugated boxes with the following information:

- Product title/description

- Barcodes

- QR codes

- Batch numbers/lot codes

- Expiration dates/best-before dates

- Manufacturing date

- Storage temperature

- Country of origin

- Net weight

- Regulatory symbols

- Company logos

- Contact information

- Pharmaceutical identifier

Printing Challenges in Commercial Carton Production

Corrugated paper's primary benefit for commercial cartons is its ability to resist being crushed or torn. The printability of cardboard is often a secondary consideration, if at all. However, it can have serious implications for displaying the critical information needed on commercial cartons.

Some of the challenges include:

- Corrugated paper is absorbent and can allow ink to penetrate deeply and spread, creating inconsistencies in print markings that affect overall readability.

- Corrugated paper tends to come in shades of brown, which is a low-contrast background when printing with black ink.

-

Recycled corrugated material often has a surface with inconsistent contrast that varies from relatively reflective to lower reflectivity.

None of these issues will likely challenge the human eye’s ability to read what is printed on a commercial carton. However, these difficulties can impede the machine reading of barcodes and the overall scannability of a commercial carton, leading to hiccups when shipping the carton.

Corrugated printing methods must use a quality printer that is properly set up on the packing line to ensure that commercial carton labels printed directly onto the cardboard are readable and machine-scannable (grade B barcodes) and that operations are efficiently and reliably carried out.

Solutions for Printing and Labeling on Corrugated Boxes

Overcoming the issues inherent in cardboard printing requires corrugated printing methods suited to porous and semi-porous surfaces. Large characters and high-resolution printing are also a plus for clearly legible and machine-readable corrugated printing. Several products provided by InkJet, Inc. offer the corrugated printing and labeling methods needed in commercial carton production.

Each solution has distinct application specialties, specifications, and cost factors. This table lists our various hardware options and notes their specifications. Additional information on each machine can be located further below on the page. Click the title in the table’s leftmost column to jump to a specific solution.

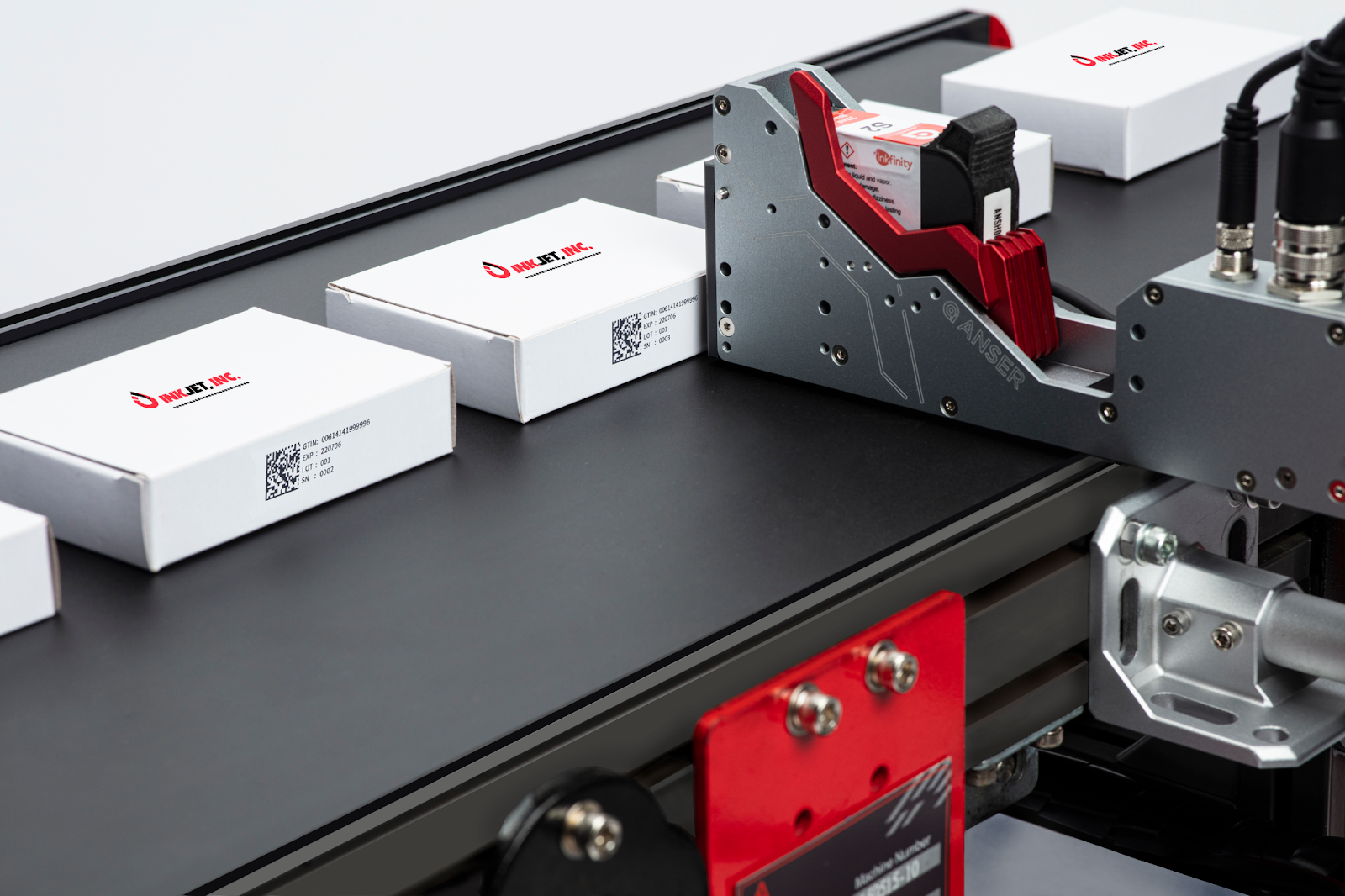

Anser X1 and A1 Thermal Inkjet Printers

Thermal inkjet (TIJ) printers are compact, cost-effective machines with impressive coding specifications. TIJs like the Anser X1 and A1 can create 600 x 600 DPI codes up to 2” tall with stitched printheads. These qualities enable TIJ operators to complete product-marking tasks and case-coding applications.

TIJ printers also offer:

- Simple Installation. TIJ printers are compact and lightweight, enabling easy and quick line integration.

-

Zero-Maintenance Operation. Thermal inkjet printers do not require printhead cleanings, ink system maintenance, or professional servicing. Users can maintain proper TIJ operation for years by performing simple cleaning tasks and following basic usage guidelines.

TIJ printers are often designed for slower speed lines and intermittent coding tasks, but some TIJ models offer high-speed capabilities. InkJet, Inc. carries TIJ printers of varying specialties and price points.

See the chart below for a closer look into how our TIJ options compare to one another:

High-Resolution Case Coders: Precision Series 18mm & 72mm

High-resolution case coders (hi-res) excel at placing high-quality images and codes on corrugated boxes. InkJet, Inc’s Precision Series 18mm and Precision Series 72mm are ideal for secondary and tertiary packaging tasks.

High-resolution case coders use powerful piezoelectric printheads to create large messages, intricate graphics, and stark images. Hi-res ink is oil-based and thicker than TIJ ink, making hi-res codes more durable and visually appealing. As case-coding solutions, Precision Series systems enable users to replace physical shipping labels with printed codes, text, and images.

Direct printing offers numerous benefits over manual labeling, including:

- Faster coding times

- Fewer material costs

- Lower risk of coding errors

- Better code durability

-

Improved print quality

In addition to these factors, Precision Series case coders provide users with these unique features:

- Internal Barcode Generation. Precision Series case coders can operate as completely standalone machines. Equipped with label design software and internal memory, Precision Series case coders allow users to create and store designs without an external computer.

- Seamless System Integration. Precision Series case coders are compatible with NiceLabel and Windows systems, enabling easy integration with external networks.

-

Dual-Head Functionality. Precision Series printers can be equipped with two printheads, allowing operators to print on two box sides simultaneously, whether for repeat images or independent codes. Users can stack heads to increase image size as well.

See the chart below for a closer look into the Precision Series’ specifications:

Laser Marking Solutions: Fiber, CO2, and UV Laser Models

Laser marking systems are perfect for companies that require high-coding speeds, reliable accuracy, and exceptional code appearance. High-output operations

frequently use laser systems to meet demanding quotas, minimize coding errors, and enhance their products’ visual appeal. As laser marking machines have become more affordable, they have become increasingly popular with smaller-scale companies.

Laser systems are more expensive than printers but do not use any consumables. Moreover, they have minimal maintenance needs and do not require annual servicing. Depending on your output needs, these factors can make laser marking more cost-effective than printing.

InkJet, Inc’s F8100C CO2 Laser Marking Machine is compatible with corrugated materials and offers the following benefits:

- Marking speeds up to 2000 characters/sec.

- 24/7 uninterrupted coding

- Reliable ingress protections

- Long laser tube life

- Enhanced high-resolution mark quality

- Plug-and-play laser module for easy line replacement

- User-friendly control panel via computer or smartphone app

See the chart below for a closer look into our laser systems’ specifications.

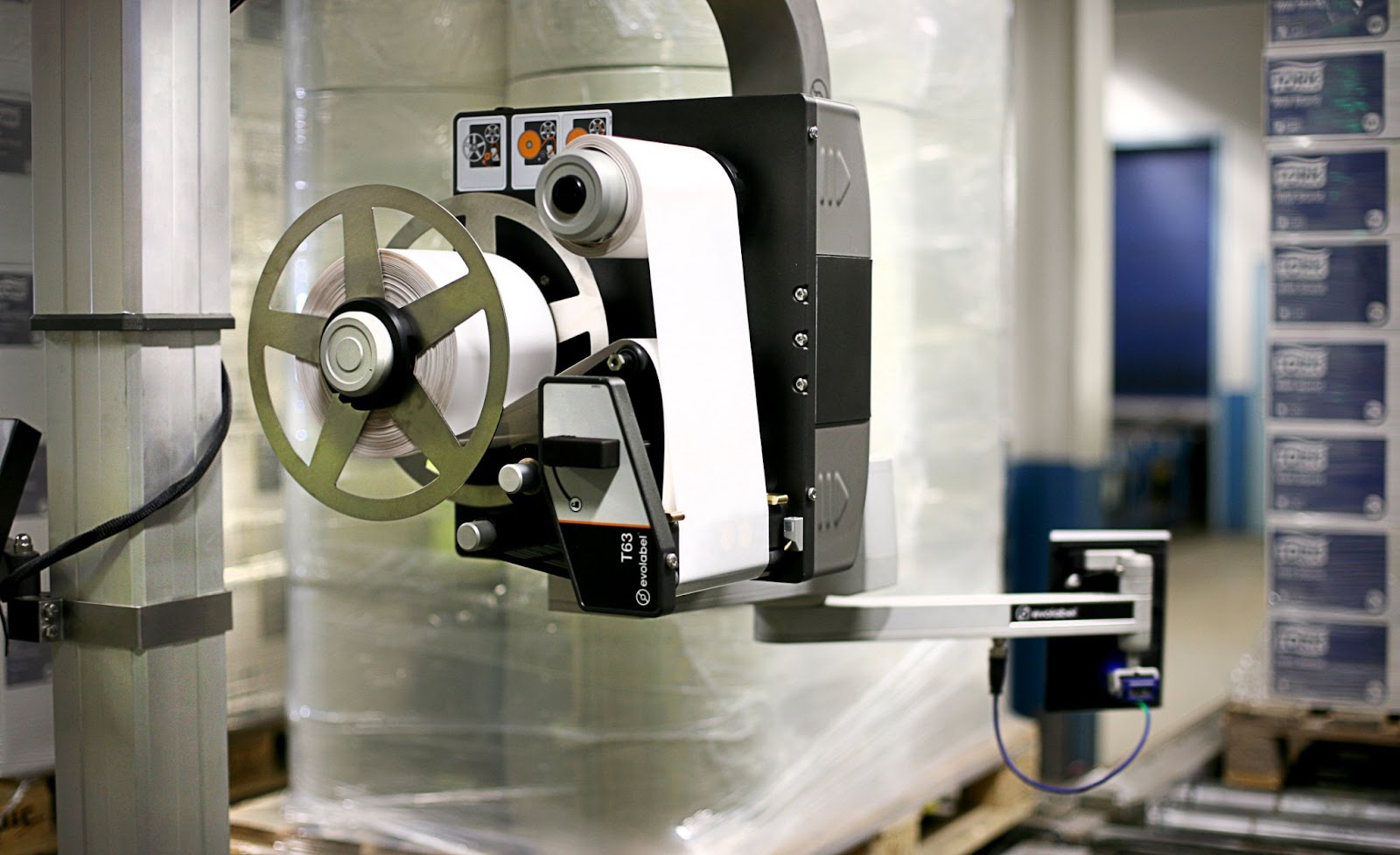

Print-and-Apply Label Machine: Evolabel Systems

Print-and-apply labeling machines (PALM) streamline the labeling process by continuously creating and applying labels to passing products or shipping cartons. Predominantly used to label shipping cartons, PALM systems can complete primary, secondary, and tertiary applications with the right equipment.

Users can customize their print-and-apply labelers to complete specific tasks. PALM systems consist of multiple components, with two of the most important being:

- The printer module prints labels on-demand.

-

The label applicator dispenses and applies each label to a product, carton, or pallet.

By selecting the ideal printer/applicator combo, you can use a PALM system to label your cardboard boxes quickly, accurately, and efficiently.

By investing in an Evolabel system, you can simplify your case package labeling process, reduce the risk of error, and maximize packaging efficiency.

High-Quality Inks for Different Packaging Requirements

InkJet, Inc. has produced high-quality inks for over 30 years. Our comprehensive catalog contains numerous formulas to better meet the needs of diverse companies.

We offer many formulas with special properties, including:

- Superior substrate adhesion

- Ultra-quick dry times

- Sunlight resistance

- Fade resistance

- Rub resistance

-

Soft/hard pigmentation

We also carry aftermarket formulas for today’s most popular printer systems. Our aftermarket options are more affordable than their OEM counterparts but perform just as well, if not better. InkJet, Inc. carries aftermarket options for printers made by the following companies:

- Videojet

- Domino, including Bitjet and Jet Array

- Markem-Imaje

- Marsh

- Linx

- Diagraph

- Willett

-

Leibinger

We also offer custom ink services for unique applications and situations.

InkJet, Inc. Simplifies Printing and Labeling on Corrugated Boxes

It’s vital for commercial carton production to proceed smoothly and without interruption by selecting the correct corrugated box printing and labeling methods. Expertise and know-how from those highly experienced with printing on corrugated material set up a production line for long-term success. InkJet, Inc. is happy to help develop the corrugated printing method for your commercial cartons that will keep production and logistics flowing smoothly.

To learn more about corrugated printing and labeling methods for commercial cartons and find the ideal equipment for your production line, contact InkJet, Inc. online or call (800) 280-3245. We are happy to develop printing methods for your brand and handle testing and validation so you can have confidence in your commercial carton production.