Printing on Flexible Packaging

Across a number of industries, flexible packaging stands as one of the most valuable and frequently used substrates on the market today. An umbrella term used to describe a range of packaging forms constructed from plastic, paper, aluminum foil, coated paper, or film, flexible packaging is valued for its cost-effectiveness and ability to prolong shelf-life. As such, bags, pouches, packages, and cartons made from flexible packaging are commonly found throughout the food industry, beverage packaging, pharmaceutical development, and personal care/cosmetics, among others.

Whether a company is producing bagged snack food or pharmaceutical blister packs, both supply chain guidelines and federal regulations require them to place traceable codes and markings on their products.

Required codes frequently include:

- Expiration/best-by-date codes

- QR codes

- 1-dimensional barcodes

- 2-dimensional barcodes

- Data matrices

- Serial numbers

- Lot codes

- Batch numbers

If these codes are missing, poorly placed, or contain incorrect information, companies may need to perform costly recalls, pay penalties, risk bad publicity, and/or sour supply chain relationships. Fortunately, industrial Tetra Pak printing isn't difficult when you have the expert help of InkJet, Inc.

By offering an array of quality printers and diverse ink options, InkJet, Inc. can help your company ensure traceable markings are placed properly and consistently.

Fortunately, industrial printing on flexible packaging isn’t difficult when you have the expert help of InkJet, Inc.

Flexible Packaging Printing Solutions

InkJet, Inc. has more than 30 years of experience in the industrial printing market and can help your company with its flexible packaging marking needs.

This table lists our various flexible packaging printing systems and their general specifications. More information on each machine can be located below. Click the title in the table’s leftmost column to jump to a specific solution.

Continuous Inkjet Printers: DuraCode Touchscreen, Keyboard, and Pigment

Continuous inkjet (CIJ) printers are non-contact production line printing systems designed to mark substrates moving at up to 300 m/min. Thanks to powerful ink circulation systems, CIJ printers can operate up to 24 hours daily without downtime. The speed, wide ink compatibility, and versatile printheads of CIJ printers allow users to mark thousands of products a day with highly legible codes.

|

All DuraCode systems can mark porous and non-porous substrates at speeds up to 320 m/min. Equipped with an IP55 outer structure and able to operate in temperatures ranging from 41-113° F, the DuraCode CIJ can withstand potentially hazardous environmental elements to deliver consistently excellent results. The DuraCode Keyboard and Touchscreen offer the same specifications and compatibility with ink formulas. The only difference between them is their input medium. The DuraCode Pigment has identical specifications as the DuraCode Keyboard and Touchscreen but uses pigmented ink instead of dye ink. |

|

|

See the chart below for a closer look at the DuraCode models’ most important specifications.

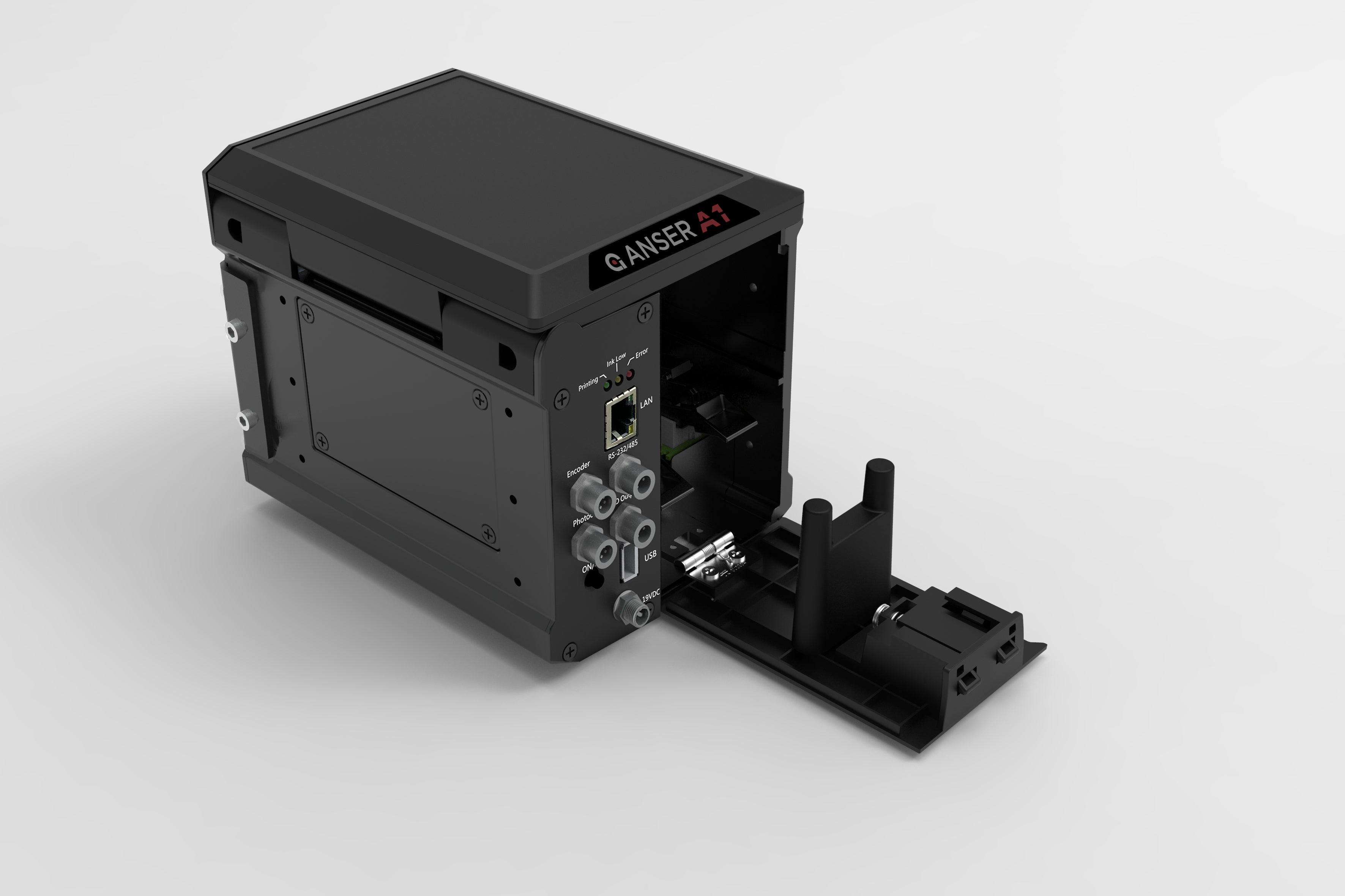

Thermal Inkjet Printers: Anser U2, X1, and A1 Models

Thermal inkjet (TIJ) printers are smaller, lighter, and more cost-effective than CIJ systems. While CIJ systems typically weigh around 100 lbs and can cost around $10,000, most TIJ models weigh 5-10 lbs and cost as low as $1,499.00.

Although thermal inkjet systems are compact and lightweight, they offer impressive coding specifications. For example, the Anser U2 Smart can create 400 x 300 DPI codes up to 0.5” tall (1” tall with the Anser U2 SmartOne). Higher-end TIJs like the Anser X1 can create 600 x 600 DPI codes up to 2” tall with stitched printheads.

TIJ printers are often designed for slower speed lines, and intermittent coding tasks including environments with tight production line space, but some models also offer high-speed capabilities. InkJet, Inc. carries numerous TIJ printers of varying specialties and price points. Our current options include:

See the chart below for a closer look into how our TIJ options compare to one another:

High-Quality Inks for Different Packaging Requirements

Flexible packaging substrates range from porous to non-porous, and if you don’t use a formula that you know will work with your specific materials, you run the risk of producing flawed codes. Fortunately, InkJet, Inc. has produced high-quality inks for over 30 years. Our comprehensive catalog contains numerous formulas to meet your needs better.

We offer many formulas with special properties, including:

- High-temperature resistance

- Alcohol resistance

- Sunlight resistance

- UV readability

- Thermochromic properties

- Different color varieties

Simplify Inkjet Printing on Flexible Packaging

Flexible packaging is a great asset to many different industries, but it can be difficult to find the right hardware and ink combination to print with precision and consistency. At InkJet, Inc., we can meet all your printing needs. With a vast portfolio of hardware and ink options, we can ensure that your operation is stocked with the right equipment to mark plastics quickly and legibly. Call us today to learn how we can help improve your operation.

For more information related to inkjet printing on flexible packaging, contact InkJet, Inc. online or by phone at 1(800) 280-3245.