Inkjet Printing on Metal Sheets, Pipes, Foil & More

Metal sheets, pipes, and foils are used by a wide range of industries, including construction, aerospace, and automotive. Product codes have become a norm within these industries because they help prevent counterfeiting, enable supply chain traceability, and provide information about production.

Required codes frequently include:

- Traceable lot codes/batch numbers

- Production date codes

- QR codes/barcode

- Anti-counterfeiting codes

- Metal grading codes

-

Serial numbers

Marking on metal, however, presents its own set of challenges. Metallic surfaces are non-porous, so for codes to be permanent, they must be applied with quick-drying solvent-based ink formulas. To further complicate matters, metal production environments are often harsh due to high temperatures, vibration, dust, and the presence of oil or other fluids.

Inkjet Printing on Metal Sheets, Pipes, Foil, & More

InkJet, Inc. has the hardware, ink, and expertise necessary to eliminate the complications often associated with metal marking and help you find the right solution for your unique production environment.

This table lists our inkjet printing solutions for metal sheets, pipes, and foil, and their general specifications. Additional information on each machine is located further below. Click the title in the table’s leftmost column for a specific solution.

Continuous Inkjet Printers: DuraCode Touchscreen, Keyboard, and Pigment

Continuous inkjet (CIJ) printers are non-contact production line printing systems designed to mark substrates moving at 300 m/min and above. Built with robust ink circulation systems, CIJ printers can operate up to 24 hours daily without downtime. The speed, wide ink compatibility, and versatile printheads of CIJ printers enable users to mark thousands of products daily with long-lasting, highly legible codes.

InkJet, Inc. meets diverse coding needs by maintaining a comprehensive CIJ ink catalog with dozens of metal-compatible formulas. We have produced ink for over 30 years and carry numerous formulas with special properties, including:

- Superior substrate adhesion

- Quick dry times on wet bottles

- Anti-transfer properties

- Rub resistance

- Alcohol resistance

- Heat resistance

- Extreme temperature resistance

- Caustic wash compatibility

- Condensation penetration

- Soft and hard pigmentation

With these options, InkJet, Inc. can provide you with a printer/ink combo that suits your line setup, meets output demands, and accounts for challenging facility conditions.

|

All DuraCode systems can mark porous and non-porous substrates at speeds up to 320 m/min. Equipped with an IP55 outer structure and able to operate in temperatures ranging from 41-113° F, the DuraCode CIJ can withstand potentially hazardous environmental elements to deliver consistently excellent results.

The DuraCode Keyboard and Touchscreen offer the same specifications and compatibility with ink formulas. The only difference between them is their input medium. The DuraCode Pigment has identical specifications as the DuraCode Keyboard and Touchscreen but uses pigmented ink instead of dye ink. |

|

|

See the chart below for a closer look at the DuraCode models’ most important specifications.

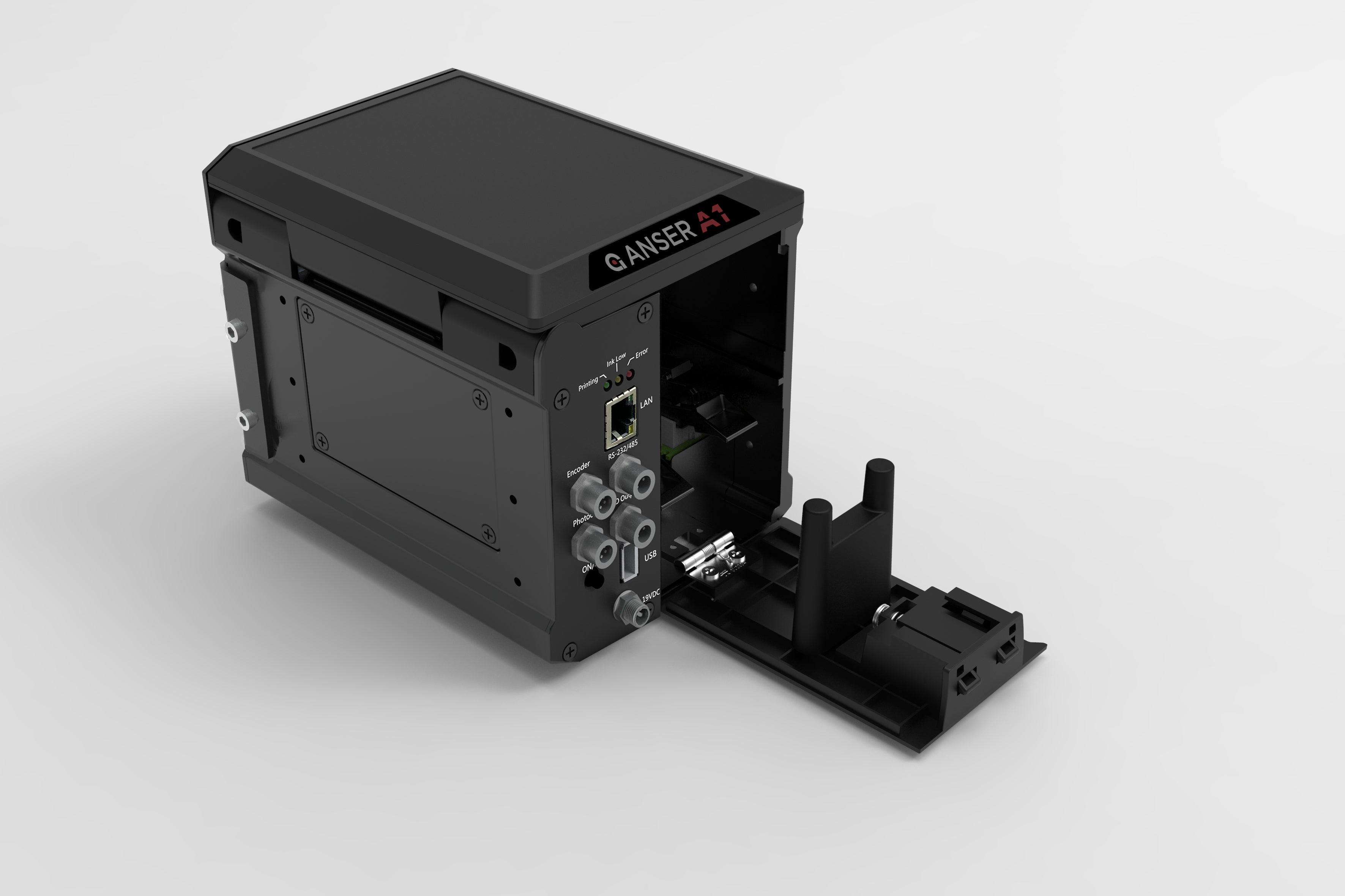

Thermal Inkjet Printers: Anser U2, X1, and A1 Models

Thermal inkjet (TIJ) printers are smaller, lighter, and more cost-effective than CIJ systems. While CIJ systems typically weigh around 100 lbs and can cost around $10,000, most TIJ models weigh 5-10 lbs and cost as low as $1,499.

Although thermal inkjet systems are compact and lightweight, they offer impressive coding specifications. For example, the Anser U2 Smart can create 400 x 300 DPI codes up to 0.5” tall (1” tall with the Anser U2 SmartOne). Higher-end TIJs like the Anser X1 can create 600 x 600 DPI codes up to 2” tall with stitched printheads.

TIJ printers are often designed for slower speed lines and intermittent coding tasks, but some models also offer high-speed capabilities. InkJet, Inc. carries numerous metal-compatible TIJ printers of varying specialties and price points. Our current options include:

See the chart below for a closer look into how our TIJ options compare to one another:

Find the Right Ink for Your Substrates

Having a well-built, reliable printer is only advantageous if you have the right ink for the job. At InkJet, Inc., we have been developing ink for over three decades, so we understand the unique chemistry behind every ink formula that we provide. We know each ink type’s ideal operating temperature, substrate specialization, and dry time, allowing us to provide each client with the perfect option for their operation.

We provide a number of metal-compatible, solvent-based ink formulas packaged as either chipped bottles for CIJ printers or removable cartridges for TIJ printers. Additionally, we offer specialty inks, including:

- OEM ink alternatives for Videojet®, Markem-Imaje, Domino, and other CIJ printers.

- Fast-drying CIJ ink for metal applications needs to be touch-dry in seconds, alcohol and heat resistant.

- Custom inks that we develop to match your exact specifications.

Inkjet Printing on Metal Sheets, Pipes, and Foil Made Simple

Metal marking can be a tricky task—the material itself requires specific ink formulas for successful adhesion, and workplace environmental issues can cause major complications if left unaccounted. Fortunately, InkJet, Inc. has the supplies and expertise necessary to outfit your operation to meet these challenges. Call today to find the perfect printing solution to meet your metal printing needs.

For more information related to inkjet printing on metal sheets, or any other questions related to printers and ink, contact InkJet, Inc., online or by phone at 1-(800) 280-3245.